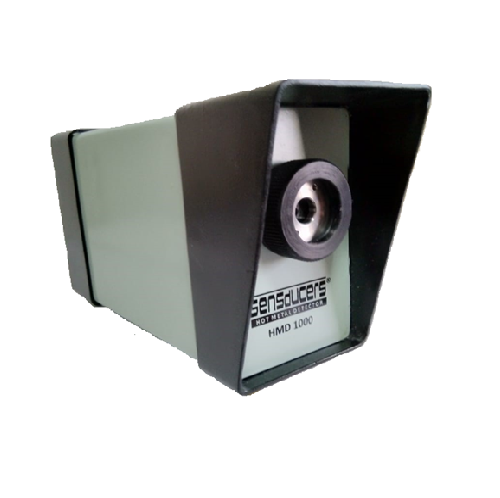

Hot Metal Detector

About Hot Metal Detector

Temperature Response Range : 350 - 1500C

Sensing Distance : 1 5 m

Dispersion Angle : 7

Supply Voltage : 24 V DC

LED Indication : Green PowerRed Detect

Output 1 : 3 wire PNP NO

Output 2 : Relay NO NC potential free

Operating Temp : 20 - 60C without cooling

Operating Temp : 60 - 70C air cooling recommended

Operating Temp : 70 - 80C water cooling recommended

Designed for Demanding Industrial Environments

Built with robust components, the Hot Metal Detector is perfectly suited for the rigors of industrial environments. Its hardened design makes it adept at handling high-temperature metals typically found in steel mills, foundries, and processing plants. The devices manual operation and quality build ensures dependable performance even in challenging conditions.

Manual Operation for Flexible Use

Unlike automated detectors, this hot metal detector is manually controlled, allowing operators to adapt and respond directly to process needs. The device does not depend on an external power supply, making it ideal for applications where flexibility and reliability are essential, and automation may not be feasible or desired.

FAQs of Hot Metal Detector:

Q: How does the Hot Metal Detector work in industrial environments?

A: The Hot Metal Detector functions by allowing manual monitoring and identification of high-temperature metal objects during industrial processes. Operators manually control the detector, using its robust design to withstand heat and provide reliable performance without automation or an external power supply.Q: What are the main benefits of using a manual Hot Metal Detector?

A: The primary advantages include greater control for the operator, high durability due to its hardened build, and independence from electrical power. This makes it a practical solution for sites where automated systems are unnecessary or difficult to implement.Q: When should I use a Hot Metal Detector in my facility?

A: You should deploy a Hot Metal Detector when you need to detect and monitor hot metal objects, especially in processes like steel rolling, forging, or foundry operations. It is particularly useful where manual oversight is crucial for safety or process integrity.Q: Where can this Hot Metal Detector be installed or used?

A: This detector can be used in various industrial environments such as steel plants, foundries, rolling mills, or any site where monitoring high-temperature metals is essential. Its manual and power-independent operation allows it to be placed virtually anywhere within these facilities.Q: What is the operating process for using the Hot Metal Detector?

A: To use the Hot Metal Detector, an operator manually positions and activates the device as needed during production. There is no setup required for automation or external power, making the process straightforward and adaptable to immediate needs.Q: How does the manual control mode enhance its usability?

A: Manual control offers direct engagement with the production process, enabling operators to quickly respond to changing circumstances and handle detection tasks with precision, especially during critical manufacturing stages.Q: What makes this Hot Metal Detector suitable for the Indian industrial market?

A: Manufactured and supplied in India, the product is tailored to the specific requirements of Indian industries. Its durability, quality, and manual operation make it particularly relevant for local facilities seeking reliable and low-maintenance detection solutions.

- Minimum Order Quantity

- 1 Piece

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in IR Pyrometers Category

Keller ITS PKL68

Minimum Order Quantity : 1 Piece

Usage : Industrial

Operate Method : Manual

Features : Good Quality

Control Mode : Manual

Automation Grade : No

IR Pyrometer 6 digit backlit LCD display 1600 deg c

Minimum Order Quantity : 1 Piece

Usage : Industrial

Operate Method : Manual

Control Mode : Manual

Automation Grade : No

Hot Metal Detector KD50 Series

Minimum Order Quantity : 1 Piece

Usage : Industrial

Operate Method : Manual

Features : Good Quality

Control Mode : Manual

Hot Metal Detector HD301N and HDA300A

Minimum Order Quantity : 1 Piece

Automation Grade : Semiautomatic